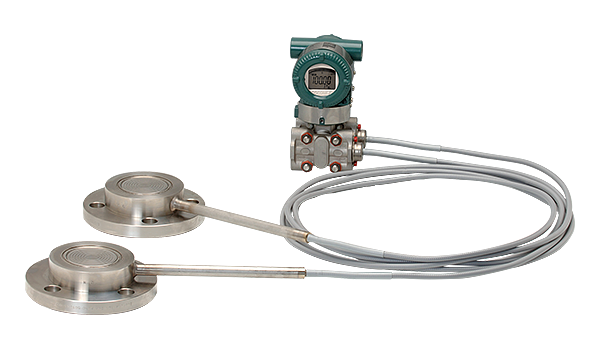

Differential Pressure Transmitter

Diaphragm Seal

October 8, 2017

Instrumentation Fittings

October 22, 2017Differential Pressure Transmitter Operating Principle

Diaphragm Seal in Differential Pressure Transmitters

Several factors are important when selecting a diaphragm seal, which are outlined below:

The type of oil inside the capillary, which is selected based on the fluid and ambient temperature.

The capillary length, which is determined based on the transmitter’s installation location.

The type of process connection, which depends on the specifications of the tank or pipe where it will be installed.

The working pressure range of the pressure transmitter, which is determined based on the maximum, minimum, and operating pressure of the process.

The material of the diaphragm seal, which is selected based on the type of process fluid.

Diaphragm seals are used to isolate the process from the instrumentation. In other words, a diaphragm seal prevents the process fluid from entering the transmitter sensor, which measures the pressure. One of the key advantages of diaphragm seals is their ability to protect pressure measuring instruments from factors such as high temperatures, corrosive fluids, or viscous substances. Diaphragm seals are connected to the transmitter via a tube or capillary filled with oil, thereby transmitting the process pressure.

At pressures above 400 millibar, Isatis Farayand Abzar Company has the capability to manufacture and couple capillaries and diaphragms to differential pressure transmitters.

ترانسمیتر اختلاف فشار , انواع ترانسمیترهای فشار, ترانسمیتر اختلاف فشار, ترانسمیتر اختلاف فشار روزمونت مدل 3051, ترانسمیتر اختلاف فشار یوکوگاوا ,