Isolating valve

عمکلرد ولو ایزولاتور

آوریل 23, 2017

Hygiene pressure and temperature measurement

می 15, 2017Isolating valve

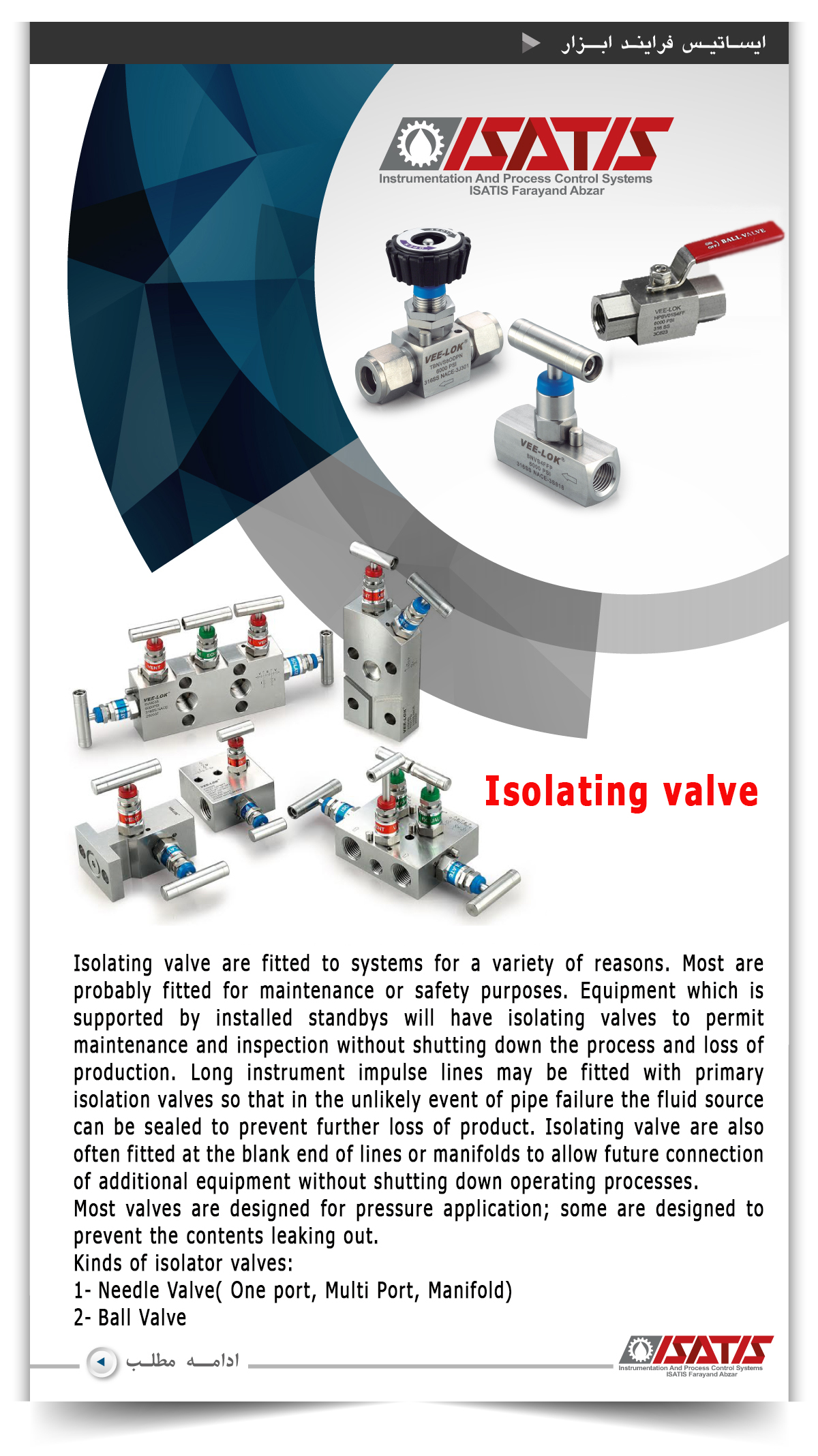

Isolating valve are fitted to systems for a variety of reasons. Most are probably fitted for maintenance or safety purposes. Equipment which is supported by installed standbys will have isolating valves to permit maintenance and inspection without shutting down the process and loss of production. Long instrument impulse lines may be fitted with primary isolation valves so that in the unlikely event of pipe failure the fluid source can be sealed to prevent further loss of product. Isolating valve are also often fitted at the blank end of lines or manifolds to allow future connection of additional equipment without shutting down operating processes.

Most valves are designed for pressure application; some are designed to prevent the contents leaking out.

Kinds of isolator valves:

- Valve manifolds

Needle valves